Gasmet provides industrial hygienists and other safety professionals with market-leading technology to conduct semiquantitative and quantitative exposure assessments as a part of Industrial Hygiene monitoring.

Uncertainty is expensive in exposure monitoring

Industrial hygienists play a vital role in ensuring that workplace conditions abide by legal limits (such as PEL) for exposure to chemical substances. These exposure limits provide industrial hygienists with a framework to protect workers from environmental hazards.

In worksites around the world, there is a growing need for improved exposure assessments. For example in the UK only, thousands of gas-related incidents are reported every year, together with numerous minor instances that go unreported. Perhaps the biggest area of improvement is the way exposure assessment results are obtained and whether the results lead to improvements in worker safety.

Typically, industrial hygiene measurements are done by collecting samples from different locations, and then the samples are sent to the laboratories to be analyzed. This kind of passive monitoring provides only one average value of a worker’s exposure over an 8-hour shift, whereas real-time monitoring provides a much more complete analysis of the worker’s gas exposure risks. This allows Hygienists to track staff workflows and minimize their exposures with real-time toxic gas concentration data.

Download the Industrial Hygiene Guide to learn how advanced technologies and proper monitoring practices can support compliance and enhance safety.

Identifying “Unknown” Gases

While many instruments are tuned to look for one target gas, it can be just as vital to monitor the “Unknown” gas(es) present. For the Hygienist this can be very valuable information when performing routine monitoring as it alerts of a leak or poor ventilation situation.

In many instances, industrial hygienists together with other safety professionals can reduce safety risks related to environmental hazards by identifying unknown smells or odors in the working environment or determining the contents of unlabeled flasks, bottles or drums, etc. This, however, can only be done with a monitoring solution that can compare compounds to a large database of gas references.

Increasing the quality of exposure monitoring while cutting costs and saving time

At Gasmet we value the work and effort industrial hygienists put into monitoring the potentially harmful contaminants of their work sites. Diligent assessment of worker operations together with accurate detecting and testing of atmospheric hazards are instrumental in assuring worker safety and smooth operations.

We want to make the process of your exposure assessment as effective as possible by increasing your ability to detect and measure harmful contaminants – in a fraction of the time it used to take. Key benefits of choosing Gasmet Industrial Hygiene monitoring solutions:

- Identify and manage risks. Simultaneously measure and identify hundreds of gases ranging from sub-ppm levels to tens of percent. Time-stamped online results provide a high level of traceability.

- One analyzer, all needs covered. Eliminate the need for multiple devices or manual lab sampling methods. The GT5000 Terra is capable of handling diverse gas measurement needs, either remotely or on-site. Additional gases and extended measurement ranges can be added without hardware changes.

- Be always ready to measure. The GT5000 Terra is lightweight, portable and can be easily used without any special expertise. Results are presented in a straightforward and meaningful ppm format, with color indicators for hazardous concentrations and presence of unknown gases

- Analyze and detect. The GT5000 Terra provides reliable results without cross-interferences from other gases. Unexpected gases can be identified from a library of thousands of gases within minutes..

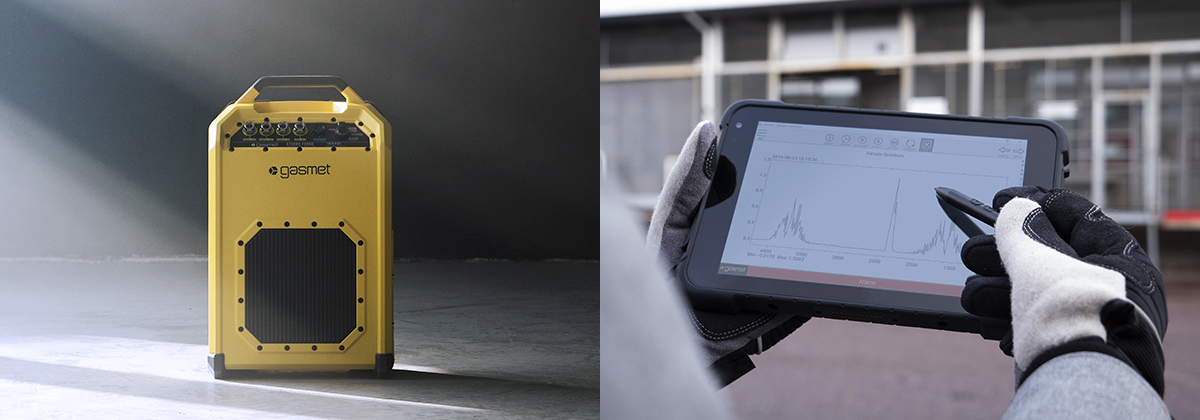

GT5000 Terra gas analyzer - market leading solution for industrial hygiene monitoring

The GT5000 Terra is a market-leading solution for industrial hygiene monitoring. It harnesses the advantages of real-time monitoring and large compound databases to aid the daily work of industrial hygienists and other safety professionals.

GT5000 Terra scans the air 10 times per second and reports to the user if there is an “Unknown” gas(es) present. These gases can then be compared against databases containing over 5,000 gas references as available from Gasmet and NIST®. This can be achieved within minutes from arriving at the worksite.”

GT5000 Terra is a lightweight and robust ambient air multigas analyzer that measures up to 50 compounds simultaneously.

Benefits of portable direct-reading instruments for industrial hygiene monitoring

Many advantages can be achieved by using portable direct-reading instruments. The possibility to measure out of hundreds is a huge time saver. As there is no need for time-consuming separate sampling and sample treatment measurements can be performed a lot quicker. This enables more comprehensive surveys of the air quality as a lot more samples can be collected and measured. Avoiding separate sampling is also cost-effective as no consumables are required for the sampling process. The GT5000 Terra gas analyzer provides an ideal solution as it offers on-site measurement of air quality without compromising on the quality of the analysis.

Do you have questions related to gas analysis in industrial hygiene? Want to be contacted by us? Drop your details below and we get back to you promptly.

GT5000 Terra – Our solution for Industrial Hygiene Monitoring

GT5000 Terra is the worlds smallest portable and splashproof multigas FTIR analyzer. It can measure up to 50 gases simultaneously, making it possible for you to detect the unexpected. Equipped with wireless communication, you can get your industrial hygiene air monitoring results in real-time on your laptop or tablet.